SEW-EURODRIVE drives innovation at automotive plant with MOVIGEAR® Installation

Willem Strydom, Electronics Business Development Manager at SEW-EURODRIVE

MOVIGEAR® with DDI cabling enables seamless condition monitoring and real-time performance tracking for optimised operational efficiency

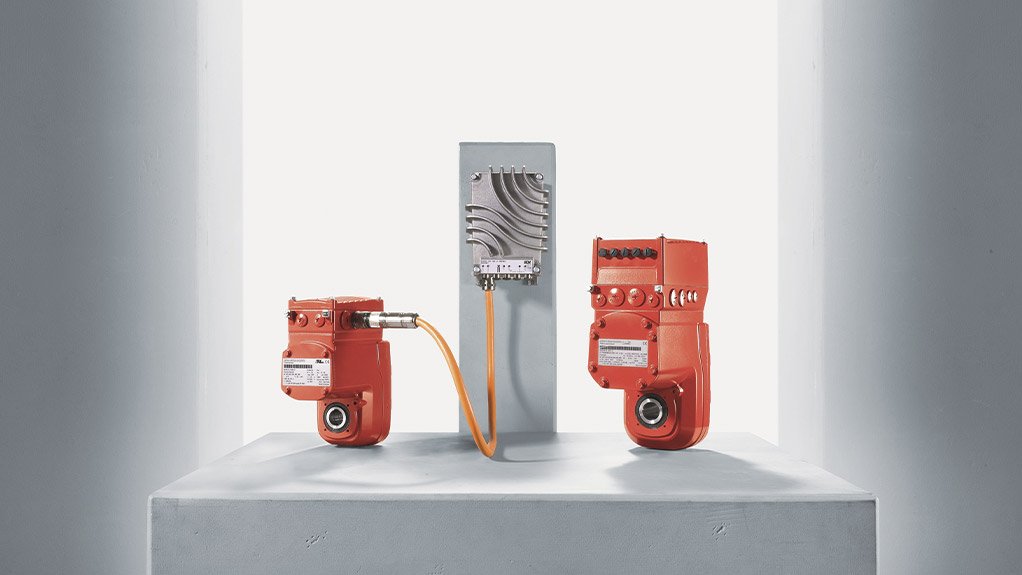

Locally assembled MOVIGEAR® units are ideally suited for mechanical conveyor applications, delivering efficient compact drive solutions with reduced wiring complexity

SEW-EURODRIVE’s local MOVIGEAR® assembly includes integration of advanced electronic components, ensuring faster turnaround times and enhanced support for smart drive solutions

MOVIGEAR® units ready for dispatch reflect SEW-EURODRIVE’s commitment to local assembly, rapid delivery and high performance drive solutions tailored for industry

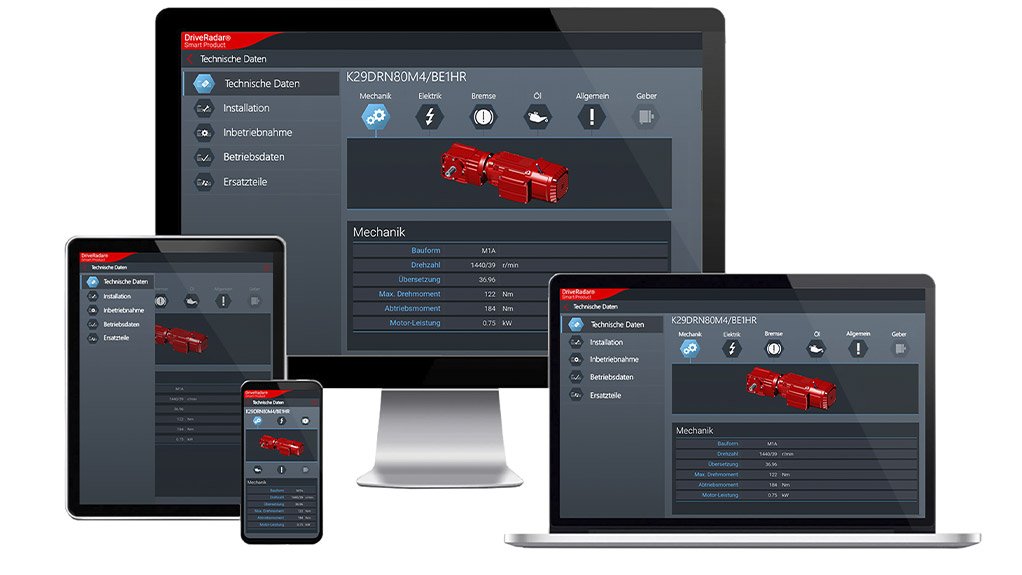

The SEW-EURODRIVE condition monitoring system features a user-friendly interface accessible on any device, anywhere in the world, enabling real-time oversight and proactive maintenance

This article has been supplied.

A major automotive manufacturer in Gauteng has boosted its operational efficiency, safety and energy savings with the installation of SEW-EURODRIVE’s advanced MOVIGEAR® mechatronic drive system in its newly expanded buffering zone.

The project saw the delivery of 150 MOVIGEAR® units, supplied to drive conveyors in a high density storage area. According to Willem Strydom, Electronics Business Development Manager at SEW-EURODRIVE, the customer’s goal was to standardise equipment to simplify stockholding and maintenance, while meeting strict safety and performance requirements. These goals were met using just two variants of MOVIGEAR®, avoiding the need for up to 30 conventional motor variants and significantly reducing inventory complexity.

Each MOVIGEAR® unit integrates a servomotor, gearbox and electronics, offering decentralised functionality with onboard communication and safety features. The system eliminates the need for traditional control panels with all units linked to a compact PLC via hybrid cabling in a daisy-chain configuration - accelerating installation and lowering infrastructure costs.

SEW-EURODRIVE worked closely with the original equipment manufacturer responsible for the conveyor installation, providing design input and onsite support during installation and commissioning. The reliability of the MOVIGEAR® units has already been proven across multiple industries, including food and beverage, and the units at this site have been running reliably since commissioning in January 2025.

A second phase of the project introduced condition monitoring using MOVIGEAR®’s digital data interface, enabling real-time tracking of performance variables such as vibration and temperature. This data is used to predict maintenance requirements, creating a digital twin of each unit to help prevent unexpected failures and extend equipment life.

With ultra-premium efficiency IE5 SEW electric motors, the MOVIGEAR® system also delivers substantial energy savings - estimated at over 38% compared to conventional motors - while offering IP69K protection for demanding environments.

By engaging from the project’s early stages through to final optimisation, SEW-EURODRIVE delivered a fully integrated and future-ready solution that supports the manufacturer’s productivity, safety and sustainability objectives.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation